ALL >> Technology,-Gadget-and-Science >> View Article

How To Evaluate A Pcb Supplier ?

Evaluating a PCB supplier is a critical step in ensuring the success of your electronic projects. The right supplier can provide high-quality products, timely delivery, and reliable support. Here are key steps and criteria to consider when evaluating a PCB supplier:

1. Quality Assurance

Certifications: Verify if the supplier holds relevant industry certifications such as ISO 9001, IPC-A-600, and UL. These certifications indicate adherence to stringent quality standards.

Quality Control Processes: Inquire about the supplier's quality control procedures, including in-process inspections, final inspections, and testing protocols. This ensures that defects are minimized and products meet specifications.

2. Manufacturing Capabilities

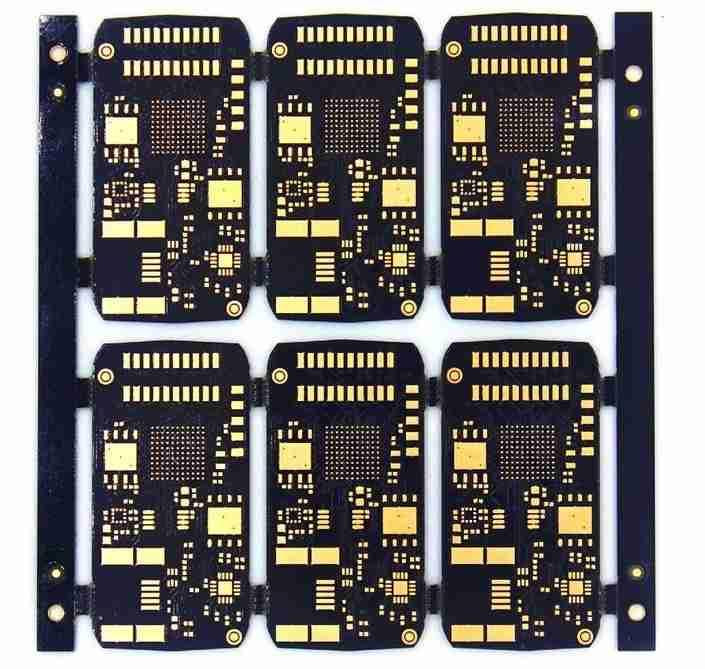

Types of PCBs: Ensure the supplier can produce the types of PCBs you need, such as single-sided, double-sided, multilayer, rigid, flex, and rigid-flex PCBs.

Technical Capabilities: Check if the supplier can handle specific ...

... requirements such as high-frequency boards, heavy copper, high-temperature resistance, and other specialized needs.

Equipment and Technology: Assess the supplier's manufacturing equipment and technology to ensure they are up-to-date and capable of producing high-quality PCBs.

3. Experience and Reputation

Industry Experience: Consider how long the supplier has been in business and their experience with similar projects.

Customer Reviews and Testimonials: Look for reviews, testimonials, and case studies from other customers. This can provide insights into the supplier's reliability, quality, and customer service.

References: Request references from the supplier and contact previous clients to get firsthand feedback on their experiences.

4. Cost and Pricing Structure

Competitive Pricing: Obtain detailed quotes from multiple suppliers and compare them. Ensure that the quotes are comprehensive and include all relevant costs.

Transparency: Ensure the supplier's pricing structure is transparent, with no hidden fees. Understand what is included in the price, such as design assistance, testing, and shipping.

Value for Money: Balance cost considerations with the quality and services offered. The lowest price may not always provide the best value if it compromises quality or reliability.

5. Lead Times and Delivery

Production Lead Times: Inquire about standard lead times for both prototypes and full production runs. Ensure the supplier can meet your project timelines.

On-Time Delivery: Assess the supplier's track record for on-time delivery. Consistent delays can impact your project schedules and deadlines.

Shipping Options: Consider the shipping options and associated costs. Suppliers that offer flexible shipping solutions can better accommodate your needs.

6. Customer Support and Communication

Responsiveness: Evaluate the supplier's responsiveness to inquiries and their willingness to provide clear, timely communication.

Technical Support: Ensure the supplier offers robust technical support and design assistance. This can help optimize your designs for manufacturability and resolve any issues quickly.

After-Sales Support: Check if the supplier provides after-sales support, including handling returns, replacements, and addressing any post-delivery issues.

7. Sustainability and Compliance

Environmental Practices: Evaluate the supplier's commitment to sustainable practices, such as responsible sourcing of materials, waste reduction, and energy-efficient processes.

Regulatory Compliance: Ensure the supplier complies with relevant environmental and safety regulations, such as RoHS and REACH.

8. Scalability and Flexibility

Production Capacity: Assess the supplier's capacity to handle your current and future production volumes. A supplier that can scale with your business is valuable for long-term partnerships.

Flexibility: Determine if the supplier can accommodate changes in order size, design modifications, and urgent requests without significant delays or cost increases.

9. Location and Logistics

Geographic Location: Consider the supplier's location in relation to your own. Local suppliers may offer advantages in communication and faster shipping, while overseas suppliers might provide cost savings.

Logistics Capabilities: Evaluate the supplier's logistics and distribution capabilities, ensuring they can efficiently handle packaging, shipping, and delivery.

Conclusion

Evaluating a PCB supplier involves a comprehensive assessment of their quality standards, capabilities, experience, pricing, delivery reliability, customer support, sustainability, scalability, and logistics. By carefully considering these factors, you can select a supplier that not only meets your current needs but also supports your future growth, ensuring the success of your electronic projects.

We are (pcb,wat,pcb manufacturer,Print Circuit Board,pcb supplier,pcb service,electronic pcb) company.Our company mainly makes PCB double-sided and high multi-layer board, HDI blind buried hole, high-frequency board, high-speed board

Add Comment

Technology, Gadget and Science Articles

1. Guide To Understanding Led Road Flares And Led Safety FlaresAuthor: Andyxiong

2. Scraping Uae Grocery Chain Data

Author: Actowiz Solutions

3. What Are Document Management Services And How Do They Work?

Author: DocSmart Solutions

4. Web Scraping G2g For Real-time Price Changes & Trends

Author: Web Data Crawler

5. Rfid System Explained: Working, Benefits, And Real-world Business Applications

Author: AIDC Technologies

6. How Probe Monitoring And Storage Monitoring Are Transforming Environmental Compliance For Modern Facilities

Author: Chris Miller

7. Compliance-ready Erp With Dynamics 365 Business Central

Author: Ahil Waseem

8. Grocery Inflation Alert Dashboard – Oos & Price Spike Monitoring

Author: Food Data Scraper

9. Scrape Grocery Data Using Apis For Real-time Insights

Author: REAL DATA API

10. Multi-platform Tour Price Benchmarking For Smarter Pricing

Author: iwebdatascraping

11. Carrefour Food Delivery Data Scraping For Market Intelligence

Author: Retail Scrape

12. Best Buy Store-level Pricing Data Scraping From Us

Author: Web Data Crawler

13. Ultrapure Water Market 2025-2035: Trends, Technologies, And Industry Applications

Author: Shreya

14. Amazon Fresh Uk Grocery Deals & Offers Data Scraping Api

Author: Fooddatascrape

15. Europe Pelletized Fertilizer Market 2025–2035: Trends, Growth Drivers, And Future Outlook

Author: Shreya